Overview of our services

- Transport of lithium-ion batteries intact after ADR defective, critical, or burnt

- UN-compliant packaging of defective batteries, modules, and cells in separate BAM-tested* UN transport containers

- Recycling and recovery of lithium-ion batteries, modules, and cells

- Storage or interim storage of lithium-ion batteries

*BAM = Bundes-Anstalt für Material-Forschung und Material-Prüfung (Federal Institute for Materials Research and Testing)

Order Management

We take care of your lithium-ion batteries! Whether intact, damaged or of any dimensions. You can easily submit your request via our online inquiry form. Please make use of the opportunity to enter initial information on the type, cell chemistry, condition and the AVV number of the industrial batteries.

We are happy to answer your questions by phone at +49 9604 90 937-0.

Transportation

Do you need support for the safe transport of lithium-ion batteries? No problem – we are also well-prepared for this. On request, our trained staff will take care of the packaging and collection in accordance with the dangerous goods regulations – even across borders.

Temporary Storage

You only want to store your lithium-ion batteries temporarily? That is also possible with ROTH.

Receipt

- Batteries are accepted and stored in secure UN containers

- Registration in the eANV Portal (transport)

- Professional collection and packaging

- Processing and recycling of lithium-ion batteries (mechanical)

- Providing of the necessary or partly legally required certificates of destruction (documentation)

We are prepared for the high demand: 9000 tons of lithium-ion batteries are to be recycled in Wernberg-Köblitz per year.

Utilization

Before the lithium-ion batteries can be dismantled for the recycling process, each battery is first identified, evaluated and, if necessary, completely discharged. This "residual energy" is not wasted but converted into alternating voltage and fed into the company's own power supply system.

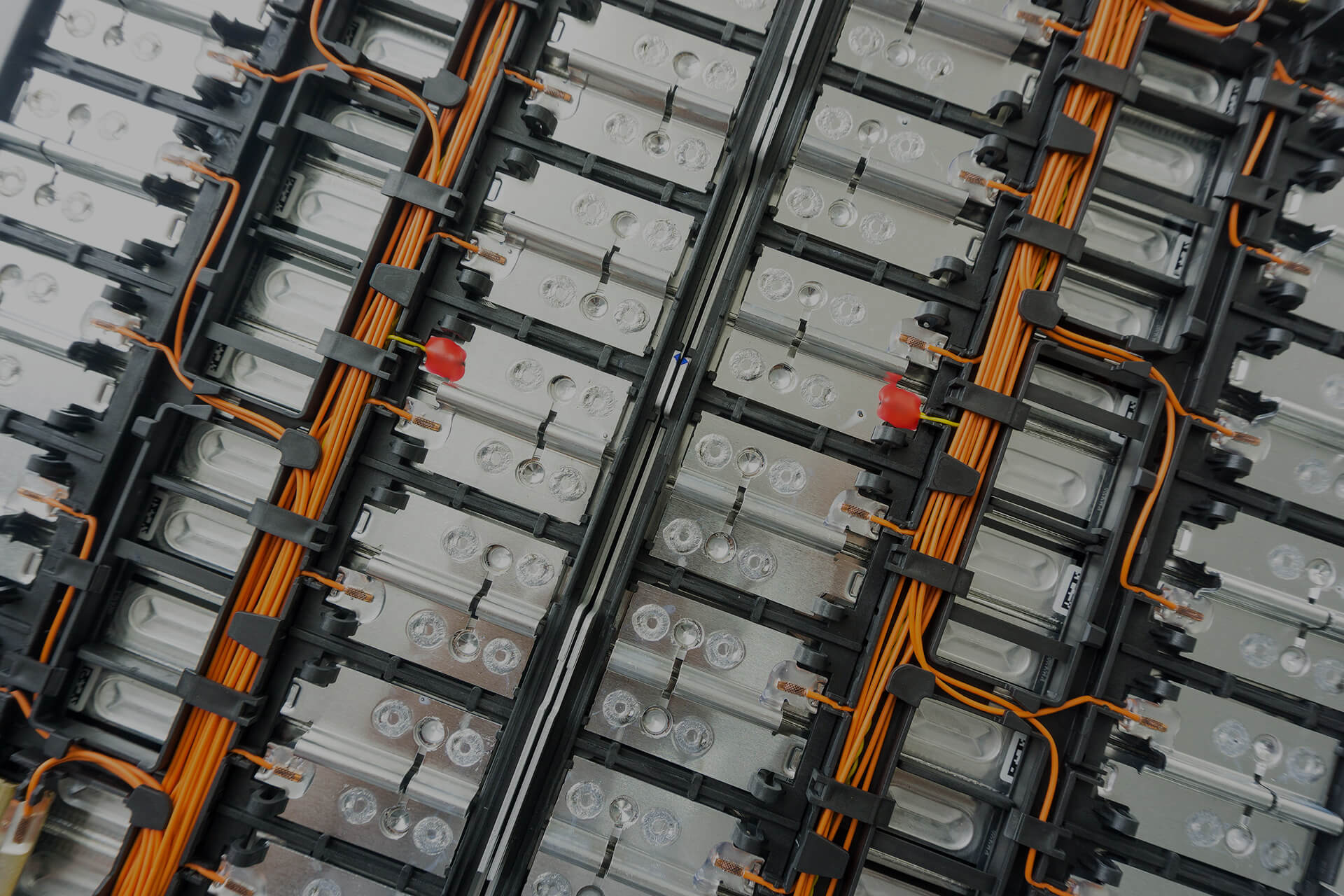

Disassembly

Mechanical disassembly follows. Much of this is done by hand, as the batteries sometimes strongly differ in design and size and thus the components can be separated most effectively.

When separating housings, cables, screws, etc., three segments are resulted:

- Metals (copper, iron, aluminum)

- Plastics

- and the actual battery module

The battery modules are now thermally pretreated separately (deactivated) and shredded into granulate with a "metal shredder". In our sorting plant, the materials mentioned are separated from the granulate via sieves, magnets, and filters.

What is left now looks like a dark, fine powder and is called black mass.

This includes graphite powder as well as the rare and valuable raw materials lithium, manganese, cobalt, and nickel.

Recycling

After the rough dismantling and extraction of the black mass, the recycling process now begins, the improvement of which we are constantly researching.

The aim is to extract the valuable materials lithium, manganese, cobalt, nickel and graphite as pure as possible via a so-called hydrometallurgical process. To put it simply, the valuable substances are dissolved out of the powder in an acid bath and separated.

We achieve this in a purity that enables the rare-earth-elements not only to be returned to the raw material cycle, but also to be used directly into new batteries.

The legal aim is to achieve a recycling rate of around 97 % and to feed it into the secondary raw materials market.

Clicking the button loads content from Google Maps. Cookies may be stored in the process.

Load mapCentral warehouse and administration

Weidachstraße 3

92533 Wernberg-Köblitz

Germany